The 8 types of waste: How to identify them in your business

Businesses have a surprising amount of waste. We’re not talking about garbage. We’re talking wasted time, effort, space, resources—anything that doesn’t add value for your clients.

Waste is often broken down into eight categories, sometimes called “the 8 wastes of lean operations.” Identifying and reducing waste can reduce your company’s costs, lead times and accidents and make employees and customers happier.

“Any activity that doesn’t add value to your customers or to your company can potentially be considered waste,” says Anish Ambujakshan, an expert on operational efficiency and a Senior Business Advisor with BDC Advisory Services. “People usually get used to doing things the same way over the years. They often forget to pause, challenge the status quo and look for opportunities for improvement.”

Identifying waste is eye-opening and also a steppingstone to operational improvements.

Anish Ambujakshan

Senior Business Advisor, BDC Advisory Services

What is waste?

The first step to eliminating waste is to understand what it is.

Waste is inefficiency that directly and negatively impacts your business, operations, customers, profit and growth.

“Let’s say there is redundant or incorrect data entry that happens during your customer order fulfilment,” Ambujakshan says. “Each error is a non-value-added activity and is a waste. Reducing that not only improves productivity, but also improves your employee morale. Identifying waste is eye-opening and also a steppingstone to operational improvements.”

Ambujakshan breaks down waste into the following eight categories. (Note that there is no standardized list of categories of waste. Some lists use different categories or have a different number of wastes, such as the “7 wastes of lean.”)

The 8 wastes

1. Overproduction

Producing more or sooner than needed.

How to spot it: Accumulation of material or work in progress found near workstations.

Consequences: Higher costs for storage and labour to move and manage material; hindrance to workspace flow, clutter.

Possible solution: Proper planning of production to meet your customer demand.

2. Waiting

Idle workers or machines.

How to spot it: Employees are waiting for instructions, tools or material to complete tasks. Machines aren’t used to full capacity or at all.

Consequences: Costs resulting from lower productivity of employees or machines; opportunity costs are incurred due to underutilized production potential.

Possible solution: Improve communication with better work instructions and better capacity planning.

3. Inefficient operations

Operations that aren’t efficient or necessary and don’t add value for the customer.

How to spot it: Products are overprocessed (i.e. made to higher specifications than customers need). Excess scrap material accumulates at workstations.

Consequences: Higher production and material costs.

Possible solution: Establish production standards.

4. Transport

Excess movement of materials, products or information.

How to spot it: Items being moved more than needed, often criss-crossing paths and hindering other movement in the facility.

Consequences: Longer lead times, increased transportation costs.

Possible solution: Reorganize workspaces or processes to reduce transport and optimize flow.

5. Inventory

More inventory than needed, excessive handling of inventory items.

How to spot it: Examine inventory turnover data, physically review inventory.

Consequences: Higher costs for inventory storage space, management and maintenance; possible spoilage and other losses.

Possible solution: Review your inventory management.

6. Motion

Unnecessary movement of people or activities.

How to spot it: Employees spend excess time getting, moving or searching for tools, material or information. Excess injuries, errors, accidents and production delays.

Consequences: Longer lead times, higher production costs, lost time to injuries, lower production quality.

Possible solution: Improve workspace layout or production processes.

7. Poor quality

Poorly made or designed products or services.

How to spot it: Employees use incorrect processes; scrap material accumulates due to rework; high rates of defects, rework, returns and customer complaints.

Consequences: Lost sales; damaged brand; delivery delays; longer lead time; higher costs for labour, material and equipment to rework products.

Possible solution: Improve quality control, processes, standards, machine maintenance, training and work instructions.

8. Misused resources

Underutilized or mismatched employee skillsets.

How to spot it: Compare skillsets and assigned responsibilities; check performance evaluations for issues.

Consequences: Employees not performing to expectations, poor engagement, opportunity cost of underused skills.

Possible solution: Review employee responsibilities to better use talent; consider training to ensure employees can perform to the best of their abilities.

How do you identify waste?

A crucial way to spot waste is physically walking through the plant or office to observe how work is done. Efficiency experts calls this a Gemba walk.

The method was pioneered by the Toyota Motor Corp., which is renowned for its trailblazing efficiency methods.

Gemba means “the real place” in Japanese. The idea is to see in person the place where value is created—how work is actually done, not what it says in policy manuals or what managers think is happening.

“The most critical element for identifying waste is seeing the operations,” Ambujakshan says. “You need to be inquisitive during a Gemba walk. Be curious to understand the workflow and the rationale behind each process step. Observe and ask questions. The way actual work is completed could be different from the way managers think it is done.”

Gemba walk needs to be one of the key responsibilities of any supervisor.

3 tips for a successful Gemba walk

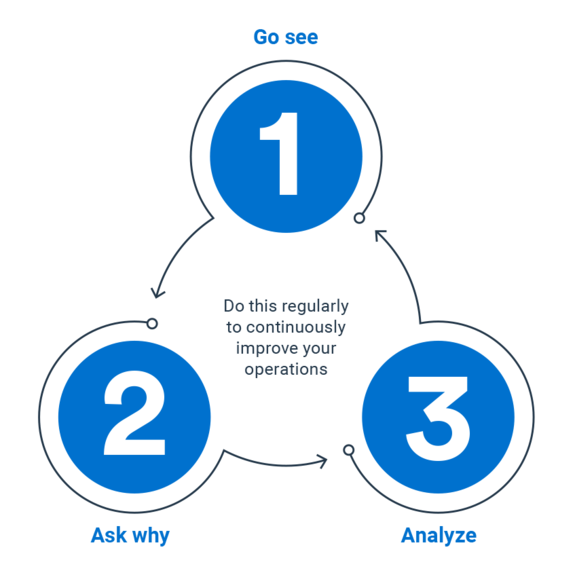

1. Go see, ask why, analyze

The Gemba walk is a time to observe and respectfully ask employees why processes and tasks are carried out in a certain way. It’s not the time to blame or evaluate employees or work on solutions.

The two principles are to (1) go see and (2) ask why. Be inquisitive, ask questions and have a collaborative mindset.

After the Gemba walk, it’s time for the third step: analyze. Meet your team to discuss your observations and identify underlying causes of problems and solutions, using tools such as root cause analysis, fishbone diagrams and Pareto analysis.

Three steps to a succesful Gemba walk

2. Use a checklist

Use a checklist to mark down observations about the eight types of waste. Afterward, teams can add action items to fix issues. Such meetings are also an opportunity to discuss progress on earlier action items.

3. Use technology

Observations can be recorded on paper, but using a cellphone or tablet can make the process more efficient and useful. A digital checklist, for instance, can be more easily shared with your team. A device can also be used to record video or take photos of issues that warrant discussion and action.

4. Do Gemba walks regularly

Ambujakshan recommends a 15- to 20-minute Gemba walk every day, though this can vary by facility size. As efficiency issues are corrected, frequency and duration can decrease. “Doing Gemba walks needs to be one of the key responsibilities of any supervisor,” Ambujakshan says. “It should be a lifestyle that reinforces a culture of continuous improvement.”

Read our free guide to learn more about the basics of operational efficiency or fill out a form to start talking with one of our experts and unlock your business’s full potential.