Economies of scale

Achieving economies of scale is crucial for any business looking to grow its profit margins. They play an integral role in your success.

Every business has fixed costs and variable costs, explains Jovanka Charbonneau, Senior Economist at BDC.

“Theoretically, fixed costs don’t increase when a business produces more, whereas variable costs go up with every unit produced,” says Charbonneau.

What’s an economy of scale?

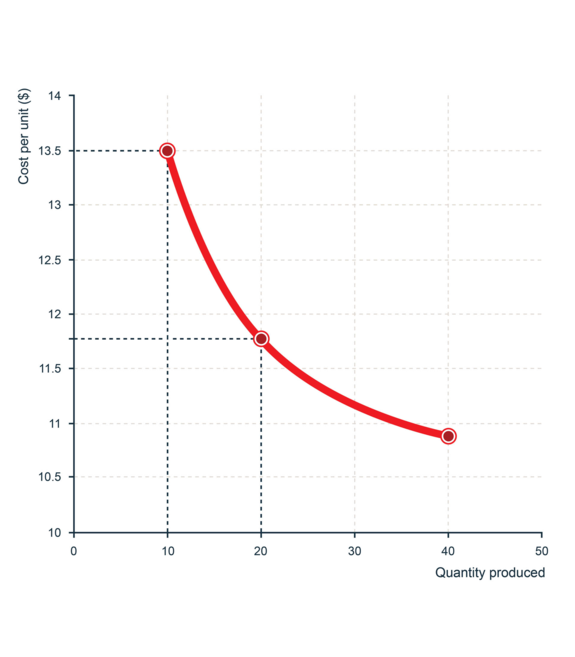

An economy of scale refers to a reduction in the cost of each unit produced as production increases.

This primarily happens when fixed costs are spread across a larger number of units produced. In that case, the average cost goes down.

The average cost is calculated as follows:

An example of economies of scale

A hairstylist serves 10 customers a day and spends $10 on products per head. Their rent and other fixed costs come to $35 per day.

Their costs will total $13.50 per head.

If they serve 20 customers, it will cost him just $11.75 per head.

They will therefore save $1.75, or 13%, per customer.

However, as production increases, the relative savings decrease if all the other factors remain the same. The reason is simple: fixed costs become less and less significant in the equation .

Even if the number of customers served were to double to 40, the economies of scale would be considerably smaller.

| Customers served | Production increase | Cost per head | Savings |

|---|---|---|---|

| 10 | - | $13.50 | - |

| 20 | +100% | $11.75 | $1.75 (13%) |

| 40 | +100% | $10.88 | $0.87 (7.4%) |

In reality, beyond a certain production threshold, fixed costs are also impacted. This is the case if you must hire more employees or purchase another plant or new equipment, for example.

Imagine that the hairstylist has to hire another stylist in order to serve 40 customers, increasing fixed costs from $35 to $50. Here’s what that would look like:

| Customers served | Initial cost per head (with one hairstylist) |

New cost per head (with two hairstylists) |

|---|---|---|

| 10 | $13.50 | $15 |

| 20 | $11.75 | $12.50 |

| 40 | $10.88 | $11.25 |

If the hairstylist can serve up to 20 customers per day, hiring another stylist to take on an additional 20 customers could result in economies of scale. Serving 40 customers with two hairstylists would cost less than serving 20 with one person. The cost per head would be $11.25 with two stylists serving 40 customers, compared to $11.75 with one stylist serving 20 alone.

Achieving economies of scale for your business

To achieve an economy of scale, you must have a lower average cost than the initial average cost.

To do this, you must take action on at least one of the three factors impacting the average cost:

- Variable costs

- Fixed costs

- Quantity produced

In our example, the hairstylist acted on all three:

Variable costs (20 x 10) + Fixed costs (35)

$11.75

Variable costs (40 x 10) + Fixed costs (50)

$11.25

Charbonneau explains that there are three main ways to achieve economies of scale.

1. Optimize your processes

Process optimization can help you reduce your costs and boost your production. Here are two examples:

| Streamlining workflows | Reducing waste | |

|---|---|---|

| Explanation | Optimizing and simplifying production methods | Eliminating inefficiencies and waste in the production process |

| Examples of tools |

Automation, artificial intelligence, project management tools |

Continuous improvement approaches, supply chain management, reuse |

| Factor: Variable costs | Better use of resources | Reducing costs of raw materials and processing |

| Factor: Fixed costs | Reducing labour costs | Reducing inventory and management costs |

| Factor: Quantity produced | Increasing speed |

2. Consider mergers and acquisitions

By combining your operations, you could reduce your variable and fixed costs related to factors such as:

- Production: You could eliminate redundancies and share resources.

- Purchasing raw materials: By increasing your purchases, you would have greater negotiating power.

- Distribution: You could gain access to more networks.

- Administrative expenses: Some expenses could be better distributed.

Often, your production capacity will increase following a merger or acquisition as well.

3. Build partnerships

Similar to mergers and acquisitions, partnerships can help you further spread out certain costs and increase production.

For example, you can share infrastructures, vehicles, technology and distribution networks.

Charbonneau also gives the example of businesses that create partnerships to order more inventory or raw materials. This helps them negotiate better prices and reduce production costs. The same situation can apply to shared expenses related to marketing or lobbying.

Partnerships between organizations sometimes lead to the creation of associations or cooperatives.

Next step

Learn how to analyze your business’s financial data and increase your net profit by downloading our free guide developed for business owners: Build a More Profitable Business.